FACTORY PIPELINE CLEANING

BENEFITS OF FACTORY PIPELINE CLEANING

Factory pipeline cleaning is a important type of pipeline cleaning that can here and there go ignored. Businesses and offices may not put as much consideration on their factory locales since they're not on the shop floor as regularly, and in light of the fact that they really are monsters to clean. In any case, ensuring your plants, storage facilities and warehouses are spotless is basic to your dominant concern, consumer loyalty and in general standing.

BETTER AND SAFER ENVIRONMENT

One of the primary advantages of factory pipeline cleaning is a better and more secure climate for employees and clients. Toward the day's end, a spotless workplace is a protected one, even in factory settings. A many people expect that factory workspaces are messy essentially in view of the idea of the work, however when you see a filthy factory area you'll rapidly understand it's not the standard.

A clean factory setting means less possibilities of employees and clients getting a contamination or sickness. Legitimate disinfection and cleanliness is the best way to diminish the development of bacteria and infections in a work place, paying little heed to what sort of industry it is. This is particularly evident in factory settings, as specific regions are left immaculate for quite a long time.

INCREMENTS FACTORY ORGANIZATION

Keeping a factory office coordinated is difficult work. The spaces are normally massive and require a great deal of scrupulousness all through day to day management to keep everything where it should be. During the course of expert factory pipeline cleaning, the accomplished cleaners will actually want to ensure that everything is the place where it should be. Thusly, when your laborers come in, they will not need to invest energy finding things that were avoided with regard to put the other day.

INCREASES PRODUCTIVITY

As we mentioned above, sound and safe conditions lead to an expansion in employee fulfillment. Worker fulfillment is directly related with usefulness levels. It's simple: cheerful employees are better specialists. They have no doubts about the company and feel regarded to the point of completely submitting their on-the-clock time to taking care of their business overall quite well.

Whenever you recruit an expert factory pipeline cleaning company, you'll likewise save time on in-house pipeline cleaning. This will permit you to use your time in a vastly improved, more effective way. If you somehow managed to attempt to have your employees help with pipeline cleaning, they'll invest less energy doing what you employed them to do in any case.

SETS ASIDE TIME AND CASH

The more regularly your employees are requiring days off, the more cash you're losing. In a similar domain, the cleaner your factory office is, the more uncertain there will be a mishap that would cost hundreds, in the event that not thousands, of dollars. Whenever machines and equipment are cleaned consistently, they'll encounter less issues. Fewer issues mean more factory efficiency and a decrease in the possibilities of machine-related injury. As the years progress, consistently pipeline cleaning your apparatus will permit you to involve them for longer, lessens general mileage, kills remaining development that can make parts break or become wasteful, and keeps everything running securely and smoothly.

Mineral acid cleaning

Our cleaning Services is insured with insurance. No hidden extras, excellent value for money. We also do not charge extra for using our equipment from High Pressure Water Jetting or high tech CCTV Colour Inspections Systems.

Our prices are fixed, no hourly charges or hidden surprises.

All our services are fully guaranteed. We want you, the customer to be happy every time at no extra cost.Mineral acid cleaning is used for the removal of metallic scale and corrosion products. It is usually applied in a three-stage operation: degreasing, metal collection, and passivation.This method has become a last resort option due to a variety of reasons, including environmental, safety, and disposal issues.

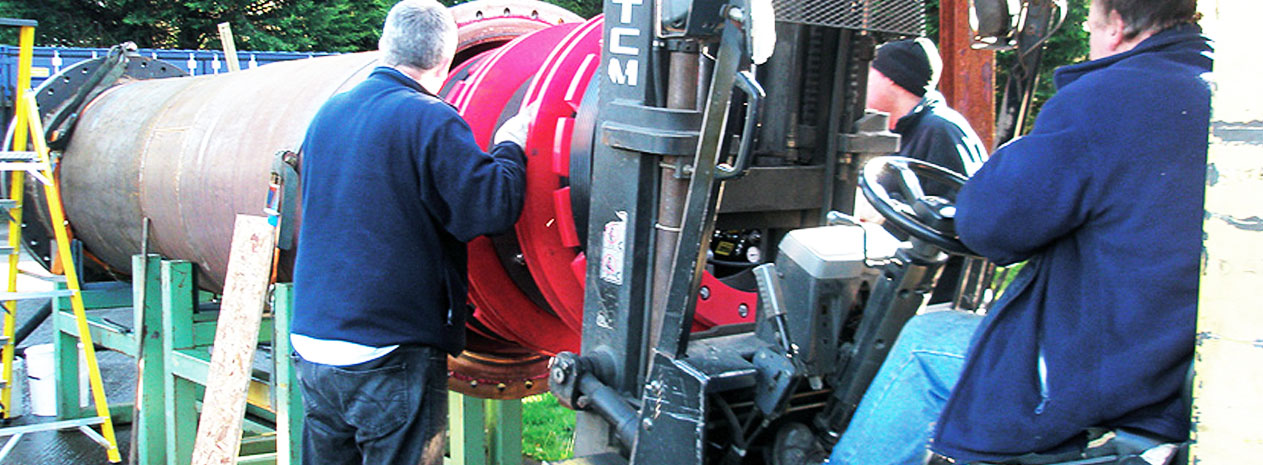

Pre-operational Factory Pipeline Cleaning /chemical cleaning

Cleaning use a wide variety of cleaning methods, chemicals, and equipment to facilitate and expedite the cleaning process.

The scope of work may include all internal pipelines. External cleaning, litter picking, and removal of graffiti may also be incorporated method.We are committed to the highest standards of customer care and service, and run a 24 hour a day service.

Performed to remove any foreign material remaining from the construction activities either on the pipe or system fabrication. Major considerations in the pre-operational phase include mill scale, corrosion products, weld scale, oil, grease, sand, dirt, temporary protective coatings, and other construction debris.

Post-operational Factory Pipeline Cleaning Services

Performed for a number of reasons, including reduced heat transfer, reduced flow, safety (e.g., H2S, pyrophoric iron, LELs, ammonia, etc.), reduced surface area (e.g., catalyst), access to full inspection, and more.

The type and frequency of post-operational cleaning varies with system design, operating requirements, and history of operation and fluid/water treatment.

Alkaline scale removal is used for the removal of organic deposit only. Like the fill and soak method, it is also used if circulation is not feasible. However, increased agitation can improve the results. Steam sparging is a common form of agitation in this method.